Appelez-nous au 1-888-826-6342

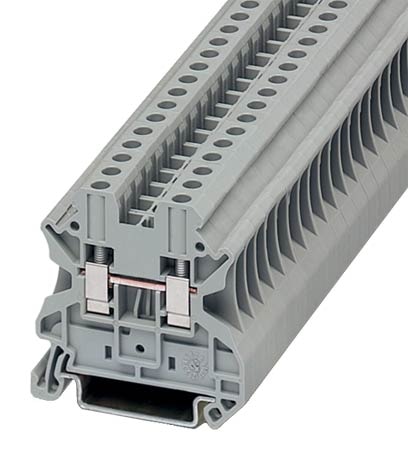

12 mm Width, Feedthrough Terminal Block, 600V/85A

12 mm Feedthrough Terminal Block

Remises de volume disponibles

Calendrier de remise sur volume

| Quantité | Prix unitaire |

|---|---|

| 1-4 | C$8.88 |

| 5-9 | C$8.70 |

| 10-24 | C$8.52 |

| 25-49 | C$8.17 |

| 50-99 | C$8.08 |

| 100+ | C$7.99 |

Ajouté à votre panier

Configuration terminée.

Veuillez ajouter au panier pour la conserver ou quitter la configuration

Veuillez ajouter au panier pour la conserver ou quitter la configuration

Échec de l'enregistrement des configurations, cliquez sur le bouton Configurer Recommencer

- Large Surface Area for Marking

- Maintenance-Free Connections

- Flexible Plug-In Bridge System

- Metal Parts Made of Tin-Plated Copper Alloy

XBUT16 Options de modèles

Voir tous les modèlesModifiez ces spécifications pour commander un modèle différente. Toutes les combinaisons ne sont pas valides. Les options compatibles avec les sélections précédentes seront en gras.

*Les options en surbrillance ne sont pas compatibles. Veuillez sélectionner une combinaison différente.

Voltage Rating

Amperage Rating

Minimum Wire Size

Maximum Wire Size

Width

Color

Insulation Strip Length

Product Family Overview

The XB Series offers a complete terminal block system with a universal range of accessories. Marking, bridging and testing accessories are standardized across the different clamping technologies -- reducing inventory and logistics costs. The modular terminal block design allows for use of the different terminal block types together or individually, providing the highest degree of flexibility.

Application Description

The metal portion of the XB Series terminal blocks are made from high-grade, strain-crack and corrosion proof copper alloys. They won’t experience any electrolytic corrosion or rusting, even when moisture is present. The metal surfaces are protected with a lead-free, galvanic nickel or tin plating. The good electrical conductivity permits only a low temperature rise. The Polyamide 6.6 housings allow for operating temperatures up to 125°C and are certified for inflammability Class V0 in accordance with UL 94.

Flexible plug-in bridge system -- All three technologies (Screw, Spring and IDC) use the same bridge system, allowing for individual potential distribution and quickly bridged connections among the same terminal block type or across different types. The XB Series terminal blocks have two bridge shafts arranged in one line, making flexible chain bridging and skip bridging between non-adjacent terminal blocks possible. Plug-in bridges are available from 2 to 50 positions. Reducing bridges are also available to connect a larger terminal block to a smaller one.

Large surface area for marking -- All XB Series terminal blocks have generously sized surface areas for labeling. This allows for clearly labeled wiring which results in reduced start-up time and simplifies activities such as testing and maintenance. There are provisions for marking individual terminal blocks and end stops, strips of terminal blocks, and large groups of terminal blocks.

Standardized testing system -- All test plugs make contact in one of the easily accessible bridge shafts. A 2.3 mm diameter test plug is available for individual measuring wires. Modular test plugs are also available for more advanced testing.

SPECIFICATIONS FOR XBUT16

Terminal Width: 12 mm

Maximum Wire Size: 4 AWG/16 mm2

IEC 60 947-7-1 in V/A/AWG: 1000/101/17-4

UL-cUL Ratings in V/A/AWG: 600/85/16-4

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in): 12 (0.47)/52.8 (2.08)/2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in): 54.8 (2.16)/62.3 (2.45)

TECHNICAL DATA IN ACCORDANCE WITH IEC

Maximum Load Current in A/Cross-Section in mm2: 101/25

Rated Surge Voltage in kV/Contamination Class: 8/3

Surge Voltage Category/Insulating Material Group: III/II

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule and Plastic Sleeve in mm2: 1.0 to 16/1.0 to 16

MULTI-CONDUCTOR CONNECTION(SAME CROSS-SECTION)

Solid/Stranded in mm2: 1.0 to 6/1.0 to 4

Stranded with Ferrules without Plastic Sleeve in mm2: 1.0 to 4

Stranded with Twin Ferrule with Plastic Sleeve in mm2: 0.75 to 10

Stripping Length in mm (in): 10 (0.39)

Thread: M5

Torque in in-lb (Nm): 22.1 to 26.6 (2.5 to 3.0)

The XB Series offers a complete terminal block system with a universal range of accessories. Marking, bridging and testing accessories are standardized across the different clamping technologies -- reducing inventory and logistics costs. The modular terminal block design allows for use of the different terminal block types together or individually, providing the highest degree of flexibility.

Application Description

The metal portion of the XB Series terminal blocks are made from high-grade, strain-crack and corrosion proof copper alloys. They won’t experience any electrolytic corrosion or rusting, even when moisture is present. The metal surfaces are protected with a lead-free, galvanic nickel or tin plating. The good electrical conductivity permits only a low temperature rise. The Polyamide 6.6 housings allow for operating temperatures up to 125°C and are certified for inflammability Class V0 in accordance with UL 94.

Flexible plug-in bridge system -- All three technologies (Screw, Spring and IDC) use the same bridge system, allowing for individual potential distribution and quickly bridged connections among the same terminal block type or across different types. The XB Series terminal blocks have two bridge shafts arranged in one line, making flexible chain bridging and skip bridging between non-adjacent terminal blocks possible. Plug-in bridges are available from 2 to 50 positions. Reducing bridges are also available to connect a larger terminal block to a smaller one.

Large surface area for marking -- All XB Series terminal blocks have generously sized surface areas for labeling. This allows for clearly labeled wiring which results in reduced start-up time and simplifies activities such as testing and maintenance. There are provisions for marking individual terminal blocks and end stops, strips of terminal blocks, and large groups of terminal blocks.

Standardized testing system -- All test plugs make contact in one of the easily accessible bridge shafts. A 2.3 mm diameter test plug is available for individual measuring wires. Modular test plugs are also available for more advanced testing.

SPECIFICATIONS FOR XBUT16

Terminal Width: 12 mm

Maximum Wire Size: 4 AWG/16 mm2

IEC 60 947-7-1 in V/A/AWG: 1000/101/17-4

UL-cUL Ratings in V/A/AWG: 600/85/16-4

TECHNICAL DATA DIMENSIONS

Width/Length/Cover Width in mm (in): 12 (0.47)/52.8 (2.08)/2.2 (0.09)

Height for 35 x 7.5/35 x 15 in mm (in): 54.8 (2.16)/62.3 (2.45)

TECHNICAL DATA IN ACCORDANCE WITH IEC

Maximum Load Current in A/Cross-Section in mm2: 101/25

Rated Surge Voltage in kV/Contamination Class: 8/3

Surge Voltage Category/Insulating Material Group: III/II

CONNECTION CAPACITY

Stranded with Ferrule/with Ferrule and Plastic Sleeve in mm2: 1.0 to 16/1.0 to 16

MULTI-CONDUCTOR CONNECTION(SAME CROSS-SECTION)

Solid/Stranded in mm2: 1.0 to 6/1.0 to 4

Stranded with Ferrules without Plastic Sleeve in mm2: 1.0 to 4

Stranded with Twin Ferrule with Plastic Sleeve in mm2: 0.75 to 10

Stripping Length in mm (in): 10 (0.39)

Thread: M5

Torque in in-lb (Nm): 22.1 to 26.6 (2.5 to 3.0)

Composant certifié UL et cULus

Accessories

Accessories for XBPT6 AND XBPT18

Software & Accessories