Appelez-nous au 1-888-826-6342

Incoloy Strip Heater 1500°F Max up to 3 kW Power

Seamless Incoloy Sheath Strip Heaters

Remises de volume disponibles

Calendrier de remise sur volume

| Quantité | Prix unitaire |

|---|---|

| 1-9 | C$918.44 |

| 10-24 | C$872.52 |

| 25-49 | C$854.15 |

| 50-99 | C$817.41 |

| 100-199 | C$799.04 |

| 200+ | C$780.67 |

Ajouté à votre panier

Configuration terminée.

Veuillez ajouter au panier pour la conserver ou quitter la configuration

Veuillez ajouter au panier pour la conserver ou quitter la configuration

Échec de l'enregistrement des configurations, cliquez sur le bouton Configurer Recommencer

- 3/4' (1.9 cm) Wide, High Temperature

- Rugged, Reliable, Premium Quality

- 500 to 3000 Watt

- 2 Terminals at One End

NSL-5403/480V Options de modèles

Voir tous les modèlesModifiez ces spécifications pour commander un modèle différente. Toutes les combinaisons ne sont pas valides. Les options compatibles avec les sélections précédentes seront en gras.

*Les options en surbrillance ne sont pas compatibles. Veuillez sélectionner une combinaison différente.

Power

Supply Voltage

Power Density

Strip Dimension

Termination

Form Factor

Sheath Material

Max. Temperature

Strip-heater advantages for higher temperature applications are offered by NS series. The heater design, materials and construction give long life for given power densities. The Incoloy sheath encloses nickelchromium resistance wire embedded in a densely compacted refractory material selected for dielectric insulation value and good heat conduction to the sheath. The small cross-section is often an advantage where space is a factor.

Clamp-on temperatures to 1200°F

Maximum work temperature depends on the watt density of the heater. Table 1 gives a few examples of work temperatures at different watt densities. Figure C-11 of the Heater Selection Nomographs page can be used to determine allowable watt densities for other specific temperatures.

Mounting

The flat top and bottom surfaces may be flush mounted or sandwiched between two heatconducting metal parts. Straight heaters can be mounted on surfaces curved to 6" (15 cm) inside radius or larger. The heater may be field bent to minimum 3 " (8 cm) inside radius. Standard strip heater clamps and clamping bands may be used for mounting.

In free or forced air, sheath temperature to 1500°F, maximum work temperature depends on the watt density of the heater. Table gives a few examples of work temperatures at different watt densities.

/* Designate voltage, i.e.; insert 120V for 120 or 240V or 480V voltage required.

/** 120 or 240 Vac only.

/*** 240 or 480 Vac only.

Clamp-on temperatures to 1200°F

Maximum work temperature depends on the watt density of the heater. Table 1 gives a few examples of work temperatures at different watt densities. Figure C-11 of the Heater Selection Nomographs page can be used to determine allowable watt densities for other specific temperatures.

Mounting

The flat top and bottom surfaces may be flush mounted or sandwiched between two heatconducting metal parts. Straight heaters can be mounted on surfaces curved to 6" (15 cm) inside radius or larger. The heater may be field bent to minimum 3 " (8 cm) inside radius. Standard strip heater clamps and clamping bands may be used for mounting.

In free or forced air, sheath temperature to 1500°F, maximum work temperature depends on the watt density of the heater. Table gives a few examples of work temperatures at different watt densities.

|  | |||||||||||||||||

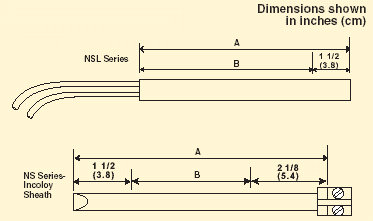

| Dimension-Inches (cm) NS Series. Incoloy Sheath | NSL Series. 10" Wire Type Leads | |||||

| A | B | Watts | W/In2 | Model No. | Model No. | Wt. (lb) kg |

| 121/2 (32) | 87/8 (23) | 500 | 32 | NS-1205/** | NSL-1205/** | .63 (.28) |

| 133/4 (35) | 101/8 (26) | 500 | 28 | NS-1405/** | NSL-1405/** | .68 (.30) |

| 157/16 (39) | 1113/16 (30) | 500 | 24 | NS-1505/** | NSL-1505/** | .73 (.33) |

| 1713/16 (45) | 143/16 (36) | 750 | 30 | NS-1807/** | NSL-1807/** | .90 (.40) |

| 181/2 (47) | 147/8 (38) | 1000 | 38 | NS-1801/** | NSL-1801/* | .93 (.42) |

| 193/8 (49) | 153/4 (40) | 1000 | 36 | NS-1901/* | NSL-1901/* | 1.0 (.45) |

| 217/16 (54) | 1713/16 (45) | 1100 | 35 | NS-2001/** | NSL-2001/* | 1.1 (49) |

| 233/4 (60) | 201/8 (51) | 1200 | 34 | NS-2401/* | NSL-2401/* | 1.2 (.54) |

| 251/4 (64) | 215/8 (55) | 1300 | 34 | NS-2501/* | NSL-2501/* | 1.25 (.56) |

| 2615/16 (68) | 235/16 (59) | 1400 | 34 | NS-2601/** | NSL-2601/* | 1.30 (.59) |

| 303/16 (77) | 269/16 (67) | 1500 | 32 | NS-3015/* | NSL-3015/* | 1.52 (.68) |

| 3315/16 (86) | 305/16 (77) | 1500 | 28 | NS-3301/** | NSL-3301/* | 1.68 (.76) |

| 363/8 (92) | 323/4 (83) | 1850 | 32 | NS-3601/* | NSL-3601/* | 1.85 (.83) |

| 39 (99) | 353/8 (90) | 2000 | 32 | NS-3802/* | NSL-3802/* | 2.00 (.90) |

| 403/4 (104) | 371/8 (94) | 2100 | 32 | NS-4302/* | NSL-4302/* | 2.13 (.96) |

| 513/8 (130) | 473/4 (121) | 2700 | 32 | NS-4827/** | NSL-4827/* | 2.7 (.12) |

| 54 (138) | 503/8 (128) | 3000 | 34 | NS-5403/*** | NSL-5403/*** | 2.75 (.12) |

/** 120 or 240 Vac only.

/*** 240 or 480 Vac only.