A faulty or unreliable temperature signal can have very expensive consequences. Believing a furnace is too cool, a process operator might increase the heat, damaging high value product inside. Alternatively, a control room supervisor might shut down a production line to avoid an indicated problem that isn’t real.

Problems like these arise when the weak voltage signal from a thermocouple or RTD is corrupted by electrical noise. One solution is to put a temperature transmitter close to the measurement point, and have that send a more robust signal. This White Paper from OMEGA Engineering discusses the advantages of using temperature transmitters and the options available. Individual sections address:

- Temperature signal corruption

- Temperature transmitter overview

- Benefits of using temperature transmitters

- Transmitter types and selection

Temperature Signal Corruption

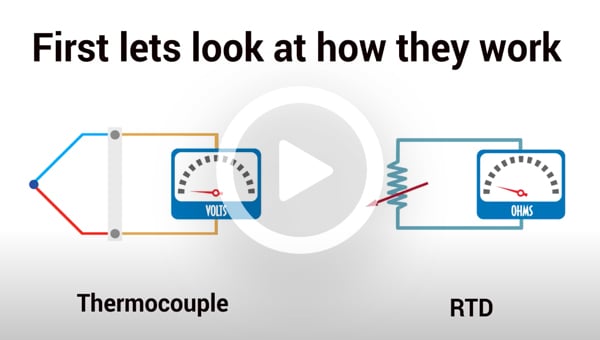

The Seebeck Effect describes how dissimilar wires joined together produce a voltage when their junctions are at different temperatures. The basis for every thermocouple, this very weak signal (typically just microvolts per degree) is used to indicate temperature. Similarly, RTD’s also give out very weak signals. These small voltages are susceptible to the effects of electromagnetic interference (EMI), and radio frequency interference (RFI).

Places like chemical processing plants, factories, and power generation plants have many items of equipment emitting EMI/ RFI. Large motors, variable frequency drives, transformers, and especially switching devices like welders, relays and solenoids, all radiate electrical signals through the air. The thin wires used for transmitting thermocouple and RTD signals act like antennas, picking up and transmitting this radiation. When the temperature signal is sent over longer distances (often the case in large scale process plants) the potential for signal degradation increases.

Temperature Transmitter Overview

A temperature transmitter is essentially a form of amplifier, filtering, conditioning and boosting the signal for better reception at the place where the temperature is read. Thermocouple or RTD wires are connected directly to the transmitter which scales the input to a 4 to 20 mA output signal, a voltage such as 0 to 10 Vdc or a digital output such as RS232, RS485, and Modbus®. This goes out over twisted pair wiring to wherever the temperature needs displaying or recording.

Temperature transmitters are available in many forms and with varying degrees of sophistication, from compact DIN railmountable units to programmable and “smart” devices with diagnostic capabilities.

Benefits of Using Temperature Transmitters

Historically, direct wiring of temperature sensors to display or data logging equipment was the norm. Increasingly though, engineers are recognizing the benefits of using temperature transmitters. These include:

- Improved signal integrity, especially over long distances. Using shielded twisted pair wiring provides even higher EMI resistance.

- Standardized output. Unlike the output from direct wiring, the 4 to 20 mA signal is compatible with most data acquisition, recording and display systems, allowing standardization of hardware

- Improved accuracy. Clipping the milliamp output to part of the sensor’s range can improve resolution and yield greater accuracy. Additionally, some transmitters can detect thermocouple drift and provide an alert before problems arise.

- Less expensive wiring. Thermocouple extension wires are usually made from the same material as the device itself, so are more expensive and more fragile than standard twisted pair wiring. Twisted pair is more easily “pulled” and as it costs less per foot results in substantial savings over the long run.

- Simplified maintenance. Twisted pair wiring stands up better in hostile environments so cable breaks and short circuits are less common and easily detected if they do occur. “Smart” transmitters can send diagnostic information so problems are understood before a technician starts tracing wiring and looking for faults

- Retrofit and upgrade flexibility. Once temperature transmitters are installed, should the process change and a different thermocouple be needed, only the sensor itself has to be changed. Conversely, a transmitter can be installed using existing direct wire connections (although EMI immunity will be lower).

Transmitter Types and Selection

Temperature transmitters are available for every conceivable application. They range from inexpensive devices providing only a robust analog signal to “smart” transmitters providing alerts for abnormal operating conditions. Physical formats range from head mount transmitters

attaching directly to the temperature probe to DIN rail-mountable transmitters for inclusion inside control cabinets.

Transmitters like the TXDIN1600 can be DIN rail-mounted for easy incorporation into control cabinets. If controls need to be accessible without opening up the cabinet, panel mount transmitters versions can be purchased.

Programmable transmitters like the TXDIN1600 from OMEGA accept universal Pt100, thermocouple, mV, mA input and provide the user with a standard two wire 4 to 20 mA output signal. Isolation is provided between input and output and all temperature ranges are linear to temperature. Designed for ease of use, our latest USB interface is fitted for quick and easy configuration.

For environments where EMI is possible and signal integrity is of high importance a high-isolation transmitter like the TX1500 series from OMEGA should be considered. Powered directly through the 4 to 20 mA signal wiring, this is protected against ground loops and electrical hazards. These are suitable for power generation situations where field mounted transmitter wiring might run hundreds of feet and be exposed to strong EMI fields. When high isolation is needed, look for products meeting the IEC 61326 standard for EMC compatibility.

Explosion proof and weather proof transmitters are available. Look for NEMA ratings to show resistance to water ingress and FM approval for hazardous or potentially explosive environments.

Universal DIN Rail Transmitter

Universal DIN Rail Transmitter

Transmitters for Demanding Applications

Transmitters for Demanding Applications

Wireless RTD Transmitter

Wireless RTD Transmitter

When selecting a temperature transmitter it is important to consider the following:

- Mounting location. Will it be head-mounted, outdoors, in a hazardous location?

- Importance of signal integrity. If a measurement error could be costly, look for a transmitter providing high isolation.

- Need for programmability. If set-points and scaling are considerations, look for this transmitter type.

- Need for “smart” capabilities. Such temperature transmitters can send alerts in the event of abnormal conditions and provide diagnostic information that helps speed maintenance.

Takeaways

Temperature transmitters have several advantages over direct wiring of thermocouples and RTD’s. In addition to higher signal integrity (from reduced EMI susceptibility) they have lower installation and maintenance costs.

Transmitters are particularly useful in field-mounting situations where long cable runs are needed, as twisted pair wiring saves money while providing high levels of EMI protection.

Transmitters are available in many different formats, for installations ranging from head-mounting to DIN rail and panel mount. Programmable and “smart” transmitters can improve measurement accuracy and provide diagnostic information and alerts.

In hazardous environments look for transmitters with appropriate protection, usually indicated by an “FM Approval” mark.