When the need arises for measuring temperatures in various industrial situations, most engineers think in terms of expensive electronic temperature measuring equipment. In many cases, though, you can do the job with less costly and much simpler methods. When the need is only for an indication that a pre-determined temperature has or has not been reached, heat-sensitive materials in the form of crayons, paints, pellets, or labels can do the job readily, inexpensively, and accurately enough for most industrial applications.

These heat-sensitive, fusible materials consist of crystalline solids. When heated, a temperature will be reached in which the solids change sharply to a liquid. The melting point is reproducible and is virtually unaffected by ambient conditions that may cause errors with other temperature-sensing methods. For example, electrical means of measuring temperatures often function erratically in the presence of static electricity, electrical “noise” or ionized air near electrical equipment.

Temperature labels are temperature monitors consisting of one or more small heat-sensitive indicators sealed under transparent, heat-resistant windows.

What is the difference between Non-Reversible and Reversible Temperature Labels?

As implied by the name, reversible temperature labels can change back and forth as needed to provide an indication of the present temperature. One advantage of the reversible labels is that they can be used over and over again. Non-reversible temperature labels are a one time usage indication that the specified temperature has been reached. Non-reversible labels are useful in a situation where an operator is not available or does not have access to the label attached to a product under test. At any future time a non-reversible label may be examined to see if the specified temperature had been obtained.

What are Non-Reversible Temperature Labels?

OMEGALABEL™ irreversible self adhesive temperature monitors consist of one or more heat sensitive indicators sealed under transparent, heat-resistant windows. The centers of the indicator circles will turn black at the temperature ratings shown on the label. The change to black is irreversible and registers the temperature history of the work piece. The exposed OMEGALABEL can be made part of the permanent record by removing it and affixing it to a service report. These conveniently applied and easy-to-interpret temperature indicating tabs find many industrial and military uses, as well as applications in research and development programs.

The OMEGALABEL will indicate a specified temperature or sequence of temperatures. The performance of the OMEGALABEL is typically not affected by transient contact with solvents, gasoline, fuel oil, lubricants, hot water, or steam. The OMEGALABEL is particularly useful in the solution of problems, which include: monitoring the safe operating temperature of equipment and processes; determining temperatures as a guide to design and material selection in research and development projects; determining temperatures as a guide to design and material selection in research and development projects; safeguarding temperature sensitive materials in storage and transit; obtaining operating temperature data of components and regions not readily accessible to other methods.

To use the OMEGALABEL, remove the backing, exposing the adhesive; press the OMEGALABEL firmly to the work surface. No special treatment is needed for the surface, although it should be clean and dry to obtain maximum adhesion.

Choose the right temperature label for your application

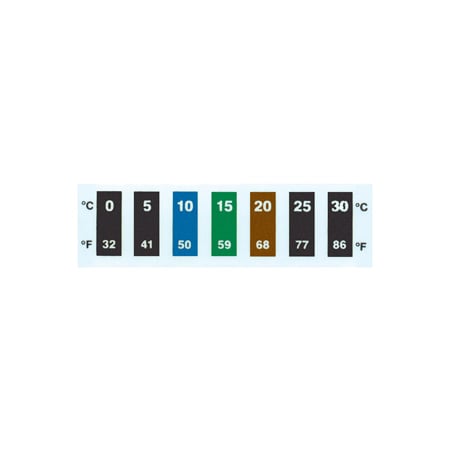

Reversible temperature sticker

Reversible liquid crystal sensor labels change appearance once a certain temperature is reached and can be used over and over.

Advantages over electronic devices

This family of fusible temperature indicators has several advantages over other methods of determining surface temperature. First, the temperature indications obtained are unquestionably those of the surface being tested. The temperature sensitive material is applied directly to the surface, and therefore changes state in direct response to that surface, and only that surface.A second advantage of using fusible temperature indicators is the fact that there is no delay in obtaining a signal. Since a mark left by a crayon or a lacquer has an extremely small mass, it attains rapid equilibrium with the surface. The use of a “massive” probe tends to prolong response time and could result in an erroneously low reading. With the use of fusible temperature indicators, there is no conduction of heat away from the surface. Nor is there any dependence on the duration of heating.

The third advantage of fusible indicators is that the technique for using them is simple and economical. Determining surface temperatures by most other means requires some technical competence and skill and, in many cases, sophisticated instrumentation. Surface temperature readings can be obtained from fusible indicators with little effort, training, and expense.