Application

As part of the quality assurance process on refrigeration equipment such as refrigerators, freezers, and cold rails, there is a need to validate that the equipment is operating within specified parameters. Performance testing scheduled at set intervals ensures that a unit is within specification and that any out-of-spec conditions are corrected. Data on minimum, maximum, and average temperature of a unit may be collected to verify that these fall within predetermined values.

Wireless temperature monitoring is growing in popularity to handle this kind of performance testing because manual temperature performance testing can be resource intensive, inefficient, and unreliable.

OMEGA products used in this application

Products

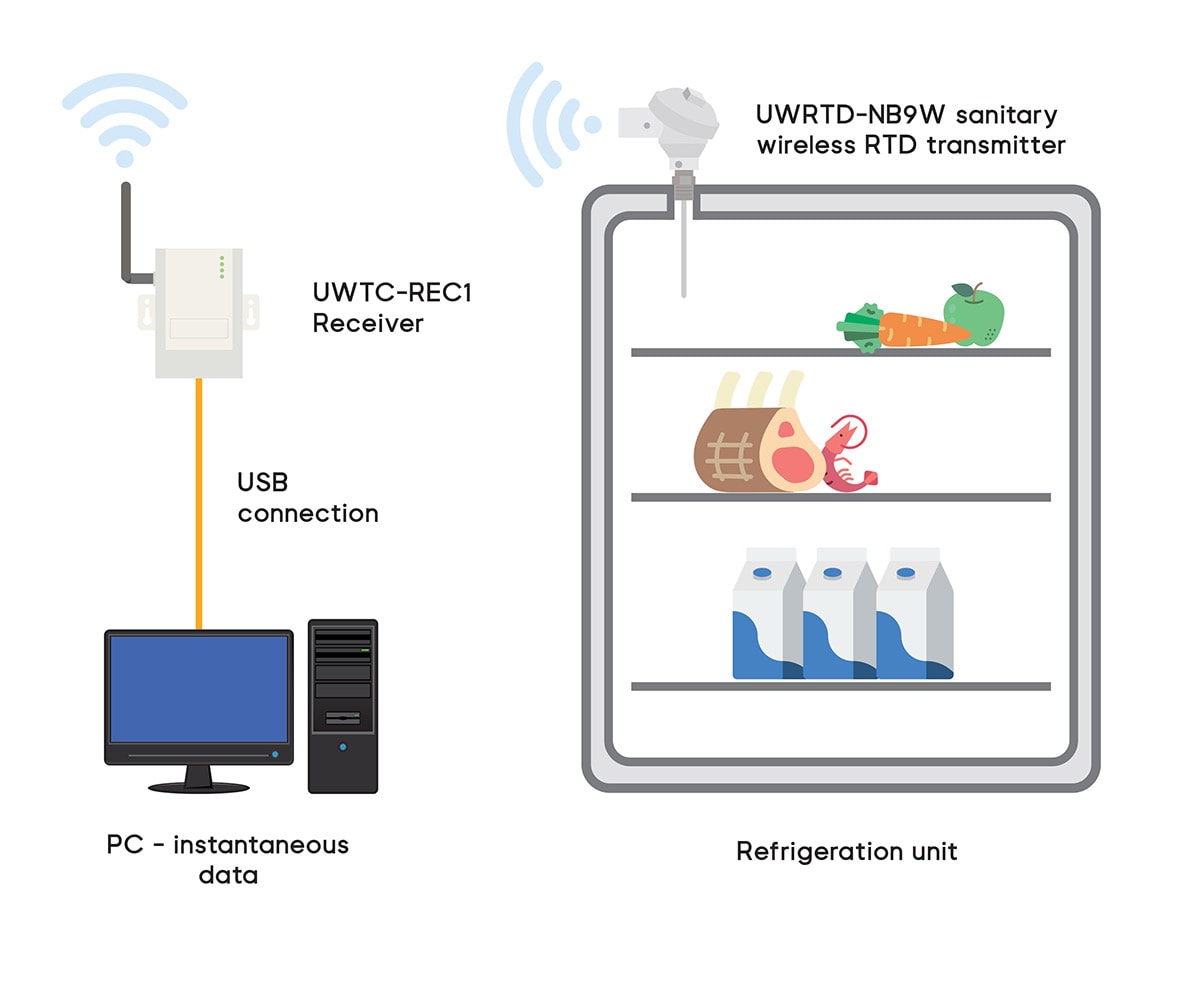

The figure above shows the schematic of the wireless temperature monitoring system. The application is comprised of three products:

UWTC-2: A wireless RTD & thermocouple transmitter with a stand-alone, compact battery powered thermocouple and RTD connectors transmits readings back to a host receiver up to 120 m (400’) away.

UWTC-REC1: A 48-channel receiver with a USB connection receives transmitted signals from the OMEGA UWTC series transmitters. Displays, logs, and graphs measure the ambient temperature data on a PC, using TC Central software, which is included with each unit.

UWTC-ANT-LR: This optional high-performance antenna extends the UWTC-2 transmitter range.

How it Works

Due to the requirement of being able to input the receiver address into the transmitters, installation and configuration should follow this order:

- Connect the receiver to your PC with a USB.

- Configure the receiver with an address.

- Verify the address of the receiver.

- Disconnect the receiver from the PC.

- Connect the transmitters.

- Assign each transmitter an ID.

- Verify that each transmitter is connecting with the receiver.

- Connect the receiver.

Troubleshooting: If a transmitter is not appearing on the PC display, the correct receiver address has not been input into the transmitter. Reconfigure the transmitter with the correct receiver address.

Results

Using a wireless temperature monitoring system, the manufacturer in this application, was able to simultaneously test multiple refrigeration products at multiple locations across its assembly area increasing its overall performance testing efficiency.

Pro Tip

When multiple locations or points need temperature monitoring, running thermocouple wire can be expensive and is vulnerable to electrical noise interference in a manufacturing environment. Wireless can also have interference issues due to RF signals, but often a long-range antenna can be used to overcome this challenge, making wireless a more affordable and easier to install solution.