Application

In the food and beverage industry, clean-in-place (CIP) maintenance is essential for meeting safety and hygiene standards while maintaining process efficiency and maximizing equipment service life. In CIP systems, process equipment is cleaned and/or disinfected by mechanical, thermal or chemical means without major disassembly. Cleaning agents, which can include acids, alkaline solutions, and water, are sprayed onto process equipment, vessels, and pipes at pre-calibrated temperatures and pressures designed to keep the process free from dirt, contaminants, and residue.

For sanitary certifications Authorization 3A and EHEDG, and to fulfill FDA requirements, it is necessary to ascertain that the cleaning cycle is effectively completed. This requires measuring the volumetric flow and temperature of cleaning and rinse agents. To do this, three discrete measurements are needed: flow, temperature and conductivity (which indicates cleaning agent concentration) of the cleaning media. Using three separate sensors to collect these measurements necessitates making three insertions into the pipework, which is more complex and costly than making a single insertion.

A new approach has been developed in which a single compact magnetic flow meter can deliver all three measurements, using a proven, reliable methodology. This makes it possible for plant operators to monitor the system’s state accurately at a much lower cost.

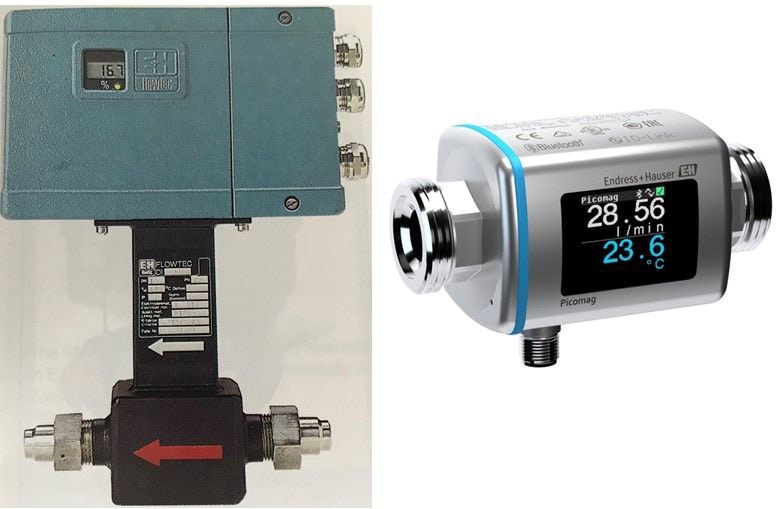

The figure above shows how a magnetic flow meter is installed in order to measure the volumetric flow of cleaning media within a CIP unit.

Products Used

Picomag Magnetic Flow Meter: This compact and cost-effective magnetic flow meter simultaneously measures temperature, flow, and conductivity of water or other process liquids. It can be configured and operated via Bluetooth and supports secure wireless connectivity with all device data accessible through the SmartBlue App. It can be flexibly integrated into any Fieldbus system through IO-Link. The Picomag’s robust housing offers a high degree of protection in harsh environments and is immune to shock as well as resistant to pipe vibrations.

How it Works

The Picomag requires no inlet and outlet runs and thus can be mounted directly before or after a pipe bend. Additionally, its exceptionally small footprint also means it can be installed in tight spaces. Bearing these attributes in mind, here is the best method to install the Picomag:

- Locate a straight section of upward-flowing pipe.

- Connect the Picomag using a welding connector or aseptic process connector.

- Configure the parameters required, such as flow range, conductivity, temperature limits, etc.

- Use the provided information to optimize processes as needed.

Results

This method makes it possible to measure cleaning media with a high degree of accuracy and ensure that the cleaning cycle is complete. The magnetic flow meter can be operated remotely and it maintains accuracy of measurement even in harsh conditions.

Pro Tip

The Picomag can readily be integrated with higher-level control systems via the built-in standard IO-Link communication system. This makes it possible to automate the CIP system to any desired level – from basic installations to advanced solutions that self-adjust for the fastest possible cleaning or shortest possible process downtimes.