Digital panel meters present numerical information that’s easy to read. Used extensively in process control equipment, they are an inexpensive way to present data from instrumentation such as thermocouples, humidity and pressure sensors. By displaying voltage or current information they can also be used to monitor the performance of electrical equipment. This White Paper from OMEGA discusses the benefits of using this versatile display device. Ten application examples are given to illustrate the range of possible uses.

Application Flexibility

DPPt Series Panel Meters

DPPt Series Panel Meters

Panel meters like OMEGA’s DPPt Series offer tremendous flexibility for builders of process control instrumentation and factory automation equipment. They accept a wide range of inputs and can be configured to display information in many different engineering units. More sophisticated models allow setting of alarm levels, will send relay signals to control associated equipment, and can even output data to a computer or data acquisition system.

The DPPt series is especially suitable for temperature monitoring and process control. Designed for connection directly to a range of thermocouples, thermistors and RTD’s, it also takes both dc current and voltage signals. This allows connection of an instruments reading, amongst other things, pressure, humidity and flow. However, any electrical signal can be taken as an input, providing it stays below maximum design levels.

Application Ideas

Here are 10 applications to illustrate the breadth of possibilities:

Oven Temperature Monitoring

Oven Temperature Monitoring

1.Oven Temperature Monitoring

Continuous ovens are used in many industries. One application is curing rubber products. Typically the oven will have preheat, curing and cool-down zones, and precise measurement of temperatures in each is essential. A digital panel meter can be configured as a temperature meter by connecting the temperature sensor to the appropriate meter input. An alarm can be set for when temperatures are outside of target range. The OMEGA® PLATINUM™ series even has the option for a relay output, so heaters could be turned off or conveyors stopped in response to a temperature problem.

Motor Current Monitoring

Motor Current Monitoring

2.Motor Current Monitoring

Electric motors have countless uses, one of which is to run fans used in industrial dust collection equipment. If resistance to the fan increases that could signal a filter blockage. Alternatively, a drive failure (like a broken belt), would be indicated by a drop in current drawn. A shunt or current transformer pulls the current down to a level the meter can accept.

Monitoring Water Temperature in a Molding Machine

Monitoring Water Temperature in a Molding Machine

3.Cooling Water Temperature

Injection molding tools often use water pumped through the tooling to cool and solidify the plastic. Predictable cooling depends on both the temperature and flow rate of that water. A digital panel meter can display water temperatures before and after it flows through the tool.

Monitoring Water Flow at a Wet Station

Monitoring Water Flow at a Wet Station

4.Monitoring Water Flow at a Wet Station

In semiconductor manufacturing it’s essential to maintain the highest levels of cleanliness. One of the measures employed is to wash the silicon wafers in high purity water between process steps. This washing is performed in Wet Stations that incorporate complex pumping and filtration systems. Flow meters monitor the movement of water through the various lines. Using digital panel meters to display flow rates allows operators to detect deviations that may indicate a problem somewhere in the system. With advanced meters like the DPPt series it’s possible to set alarms for excess or low flow conditions and even send signals to suspend operation until a problem is resolved.

5.Exhaust Temperature in an Engine Dyno Cell

Dynamometers are used by vehicle manufacturers and builders of performance engines to test engine output. The engine is mounted to a frame and its output shaft connected to a load such as an impeller immersed in water. Controls allow technicians to put the engine through a series of tests. Mounting temperature sensors in the exhaust ducting and displaying the temperatures on a digital panel monitor allow observation of abnormal conditions such as pre-ignition.

6.Welding Current

Nondestructive verification of weld quality is difficult to perform, so it’s important to monitor welding parameters. By using a shunt it’s possible to bring down the current and voltage used at the welder to a level that can be handled by a digital panel meter, allowing it to act as a process meter.

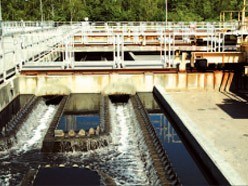

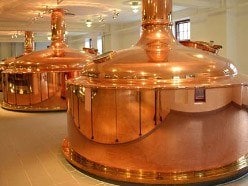

Monitoring Pressure of Brewing Vessels

Monitoring Pressure of Brewing Vessels

7.Pressure Monitoring

Brewing is an example of a process where pressure monitoring is useful. Gas is released during fermentation and could build up to dangerous levels. A pressure sensor can send a current signal to a digital panel meter configured to display internal pressure. An alarm function ensures process operators are notified of any deviation from normal operating conditions.

8.Protection of 3-Phase Motors

Large industrial motors can be sensitive to fluctuations in voltage across the phases. Digital panel meters allow monitoring of incoming voltage, enabling prompt detection of any problems and can even be set to operate as a frequency meter. Voltage imbalances across the lines, high or low voltage, and even dropped lines can all be detected and alarms triggered as needed.

9.Liquid Level Measurement

Many food and chemical processes move liquids between storage and processing vessels. Level meters are frequently used in these tanks to show process operators how much liquid they contain. In one design a float containing magnets moves up and down a shaft. Reed switches send an analog current signal from 4 to 20 mA indicates the position of the float. Taking this signal into a digital panel meter configured to convert current to volumetric units lets operators monitor vessel filling and emptying.

Humidity Monitoring is Critical in Wood Processing

Humidity Monitoring is Critical in Wood Processing

10.Humidity Measurement

After felling, hardwood lumber is dried slowly in special purpose kilns. Precise humidity control is essential to avoid splitting or cracking the wood. Mounting humidity sensors in the inlet and exhaust ducting, as well as the kiln itself, allows operators or a process controller to maintain the optimal drying conditions, minimizing both drying time and damage to the hardwood. Humidity sensors typically provide 4 to 20 mA or 0 to 5 Vdc outputs which can go straight into a panel meter like the PLATINUM™ digital panel meters.

Versatile and Easy to Use

Modern digital panel meters are a highly flexible tool for displaying essential process information. Meters like the OMEGA® DPPt accept direct inputs from temperature sensors and also handle dc voltages and currents. Configurable to provide a display in wide range of engineering units, these devices are a boon to anyone designing and building factory automation or process control equipment. If you have a digital panel meter application OMEGA has a product to suit.