Ultrasonic sensors send sound waves that range above the range of human hearing, (over 20 kHz). These sound waves echo off the surface of a set target, the waves repel off the target (i.e. the base of a vessel containing juice and pulp), and return to an ultrasonic level transmitter to record flow and level monitoring equipment.

Ultrasonic level transmitters are used to monitor flow and level of liquids in the food production industry. Methods for Safety Integrity Level (SIL) and instrumentation are engineered for reliability in testing and certification in compliance regulation in liquid manufacture and food production industries.

Measurement of Juice Level in a Vessel

Ultrasonic level transmitters are used to monitor flow and level of liquids in the food production industry. Methods for Safety Integrity Level (SIL) and instrumentation are engineered for reliability in testing and certification in compliance regulation in liquid manufacture and food production industries.

Food science has recognized the value of using ultrasonic waves for safe and accurate measurement and monitoring when sensory systems are needed for detection and precision monitoring of liquid levels.

How Ultrasonic Level Transmitters Work

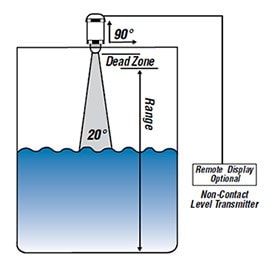

Non-Contact Level Transmitter

Non-Contact Level Transmitter

Continuous ultrasonic pulses monitor levels in vessels while mounted at the top of the tank above the blocking distance. Pulses travel through the empty distance of the vessel, above the fluid surface in the tank, traveling through the fluid (juice, pulp or other aqueous fluids) to the bottom of the tank. The travel distance from the liquid level to the bottom of the tank is measured by the ultrasonic sensor and the detection target at the bottom of the tank.

The calculation of the time it takes for the ultrasound pulse signal to travel from the ultrasonic transmitter to the target and back is dependent on the accurate standard of the speed of sound in the air environment. Dividing the pulse travel time by two, and multiplying the result by the speed of sound, gives the precise level of juice in the vessel.

Formula:

Level = particular airspeed of sound in manufacturing environment X time delay ÷ 2.

Hazard Analysis and Critical Control Points (HACCP)

Food manufacturers are regulated by the Food and Drug Administration (FDA) Principles Application Guidelines. During manufacturing and food production of colloidal fluids, monitoring of critical limits of each control point to prevent, limit or reduce safety hazards to an acceptable level, come under the Title 21 Code of Federal Regulations (CFR) Part 120.1(a). Proof testing is an important part of validating the safety function of a level instrument.

Level Instruments such as switches, ultrasonic level transmitters, RF level transmitters, flush mount pressure transducers, and other SIL instrumentation are systems in place to prevent and regulate the possibility of hazardous events. This equipment is certified to detect an overfill condition in a vessel or tank. End user testing procedures, such as proof level or partial proof testing of level instruments, to maintain SIL ratings prevent failures of instruments or the overflowing of tanks, maintaining appropriate safety levels. The IEC 61508 standard provides a systematic approach for the design and testing of products in safety-related applications. The IEC (International Electro-technical Commission) defines SIS (Safety Instrumented System) and compiled the standards. Level instrument requirements compliance is defined by IEC 61508, which applies to food production manufacturers and suppliers of SIL products.

Measuring a Single Discreet Liquid Height

Point level measurement sensors mark a pre-set liquid level condition in the juice or pulp manufacturing process. These sensors monitor over-fill conditions, triggering a high alarm function.

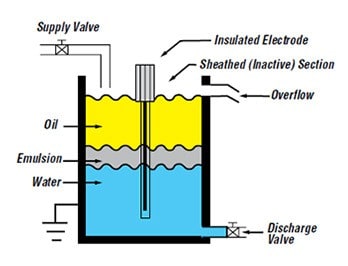

More sophisticated continuous level sensors provide level monitoring of entire systems. Instead of simply monitoring a critical point in the juice production process, level interface detection sensors measure liquid levels within a specifically set range.

Analog output directly correlates with juice or pulp levels in tanks or vessels. The system can be linked to a visual indicator and a process control loop that creates the complete level monitoring management system.

Measuring the Level With a Pressure Transducer

The level of the liquid can be calculated using a pressure transducer and the following equation.

p = h ρ g (1) (N/m2, Pa, lbf/ft2, psf)

Where:

p = pressure or ρ = density of liquid (kg/m3, slugs/ft3)

h = height of the fluid column, or depth in the fluid at which the pressure is measured (m, in)

and

g = the gravitational, (acceleration), constant (9.81 m/s2, 32.17405 ft/s2)

The Advantage of OMEGA® Transmitters and Transducers in Juice Production, Food Production, and Liquid Manufacturing

Capacitive (RF) Point Level Switches

Capacitive (RF) Point Level Switches

If your operation requires a micro-machined, silicon sensor designed to provide a very stable transducer with exceptionally high accuracy, ideal for pressure or level applications, the OMEGA® PX409S-USBH sanitary series provides long-term stability. Our 3A approved sanitary series connects directly to your PC or enterprise setup. It comes complete with standard USB cable termination for easy setup and accurately logging data and quickly charting your readings. The fitting pressure transducer is ruggedized with a secondary containment system, gage and absolute pressure to 600 psi. Install the pressure transducer inside the bottom of the vessel. The compound gage provides ±10 inH2O to ±15 psi. The sealed gage 100 to 600 psi, vacuum 10 inH2O to 15 psi, and barometric ranges include 32 inHg or 1100 Torr.

The installation and operational software is included free. If you like the PX409S-USBH make sure the inside the vessel is the same pressure as outside. If you do have a differential of pressure inside the vessel, it is better to use a differential pressure transducer. When the juice product, or another fluid, contains pulp or flesh, the use of a flushed pressure transducer is mandatory. Otherwise, the flesh will block this transducer.

In fact, OMEGA is a one-stop source for all your process measurement and control parts and system devices. Pressure transducers can be fitted for high-performance thin-filmed pressure transducer specifications, intrinsically safe pressure transmitters, and state-of-the-art silicon technology to micro-machined silicon transducers with wet/wet differential pressure. If your operation needs specs reaching beyond our standard models, we offer custom designs engineered for general purposes, flush diaphragms, hazardous locations, heavy duty industrial - high accuracy and those specific to your PC board mountable solutions.

Whether your food production or other manufacturing concerns are level consistency, sanitary, submersible, or for any specific purpose, our design engineers can meet your challenges. OMEGA’s capacitated (RF) point level switches series LVCN6000/7000 are ideal for low and high-level detection monitoring of both liquids as well as solids.